Having clear procedures in place for specific welding techniques and qualified welders to carry them out is incredibly important. It ensures compliance with UKCA accreditation, is part of Factory Production Control and ISO9001 Quality management systems. By having qualified weld procedures in place, proven welding parameters can be set to achieve welds which are comply with the required acceptance levels in multiple areas. Our professional team have extensive experience with the procedure and welder qualification process. By working with S.T & W Inspections, you can also benefit from our consultancy on new procedures, a visual inspection course for welders, and Destructive Testing services from our sister company, S.T & W Laboratories. Call 01795 432 634 to benefit from our expertise.

Welder Qualification

Welders are qualified on specific procedures and can have their status renewed every six months. After two to three years, they must be requalified to ensure their work still meets the acceptance criteria within the procedure and complies with the relevant standards. Our team contains RWCs (Responsible Welding Co-Ordinators) who can carry out this re-qualifying process and provide confidence that the welder’s output is fit for its intended use. We can also assess welders within the facilities of our sister company, S.T & W Laboratories.

Get in touch with our team

To learn more about our welding qualification and procedure services, contact our team on 01795 432 634 or email info@standwinspections.co.uk. You can also complete our contact form for a same-day response.

Consultancy services for new procedures

We can be consulted on the development of new weld procedures, allowing businesses to benefit from our industry expertise. Our team will ensure that these procedures are created in line with the standards that apply in your industry, ensuring that the welds will be fit for purpose.

Courses for welders: Visual Inspection

As a company it is beneficial to have welders who are trained and competent to be able to visually inspect welds to the required acceptance levels. This enables them to take some responsibility for their day-to-day output where NDT is not being carried out. We offer a course for welders that is designed to teach the theory behind Visual Inspections and provide training on relevant industry standards so they can identify any surface defects or discontinuities that will require attention. This allows fabrication companies to streamline their processes, reduce costs, and build up in-house resources.

S.T & W Laboratories:

Our sister company

Our sister company, S.T & W Laboratories, provides a controlled environment for offsite testing. A number of Destructive Testing methods can be carried out using a sample of the weld, confirming its compliance. These include:

Hardness Testing

Hardness Testing involves indenting a sample to ensure that the material’s hardness has not been adversely affected during the welding process, particularly within the heat affected zone (HAZ), parent material, and weld material itself.

Macro Inspections

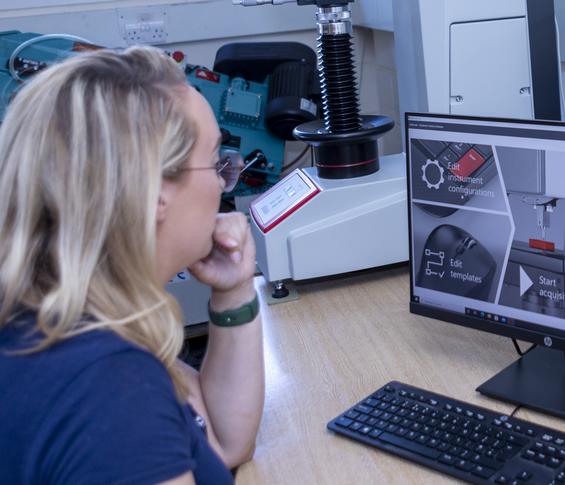

Macro Inspections are used to inspect a weld for defects in close detail. The surface of the sample will be polished to reveal the fusion face of the weld and parent material for inspection under magnification.

Fracture Testing

Fracture Testing is used to determine the level of stress that is needed for a pre-existing flaw in a weld to propagate and cause it to fail. This pre-existing flaw is made by our lab technicians prior to the test. The fractured sample can then be inspected to reveal any defects embedded in the weld.

Working with

S.T & W Inspections

At S.T & W Inspections, we deliver the highest standard of service when ensuring our clients’ components are compliant with the relevant standards. Innovation is one of our core values – we can solve any problems that arise onsite or within a laboratory setting. Our NDT services are comprehensive, offering whichever technique you may need to adequately assess your welds. We are also available for call outs and can get technicians to attend your site with short notice.

Contact

S.T & W Inspections

If you are interested in our weld qualification and procedure services, contact our team by calling 01795 432 634 or sending an email to info@standwinspections.co.uk.